If the reference model has a coordinate system component interface configured you can quickly place a die form reference part as an on surface coordinate system or by using component interfaces.

Creo sheet metal lance.

Conversion feature is used for edge rips and rip connects.

Convert a part to sheet metal.

Using a variety of y and k factor bend allowance calculations designers can create flat patterns of the designs.

With creo 4 now it s just as easy.

First shell is made in solid part second shell is for conversion to sheet metal.

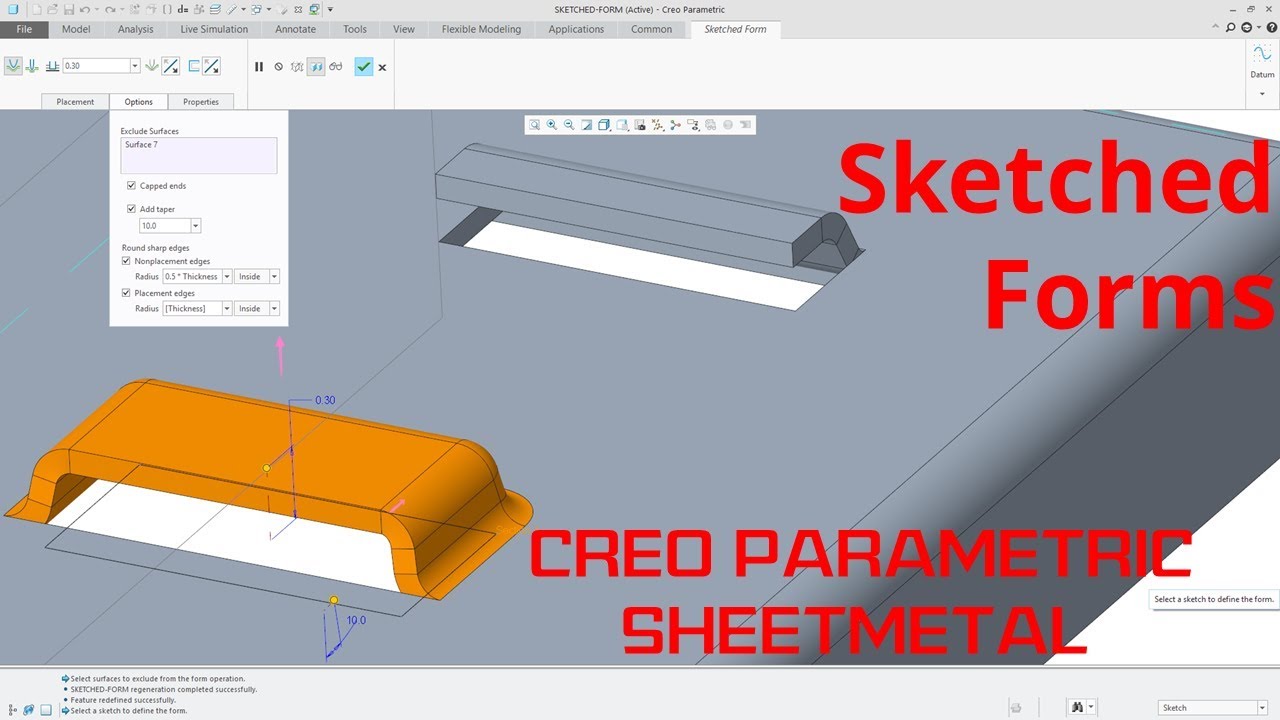

Creo sheet metal tutorial advanced creo beginner tutorial creo sheet metal tutorial advanced level.

For this part i would use double shell method.

Sheet metal advanced level s.

What happened to this functionality.

Now that you have a sheet metal part just go to the edit bend.

When creating flat wall you have at corner of the bend line a white box which can be used for extending and.

See convert a solid part into a sheet metal part for details.

First shell thickness defines flange size.

In the creation.

925 423 7496 lawrence livermore national lab 7000 e.

In this tutorial we will learn about the basic techniques related to sheet metal functionality of creo parametric by modelling a cover.

Creo sheet metal training.

I don t use sheetmetal mode often i m trying to add a hem to a part and i don t find anything in the creo 2 update training on it search for hem in creo turns up nothing.